Installation examples /Interior high-speed doors /Food processes

These first stainless steel doors have been operating in the presence of hot water + detergent spray since 1992!

Nergeco's food processes doors in a ripening room: high salinity and humidity, ideal environment for showing the superiority of multi-composites over stainless steel.

Nergeco high-speed doors, located at the entrance to the yoghurt cooling tunnels of a Senoble Ibérica factory, partner supplier to Mercadona, Spain's leading retailer.

Use of rapid automatic flexible doors in greenhouse - Mexico

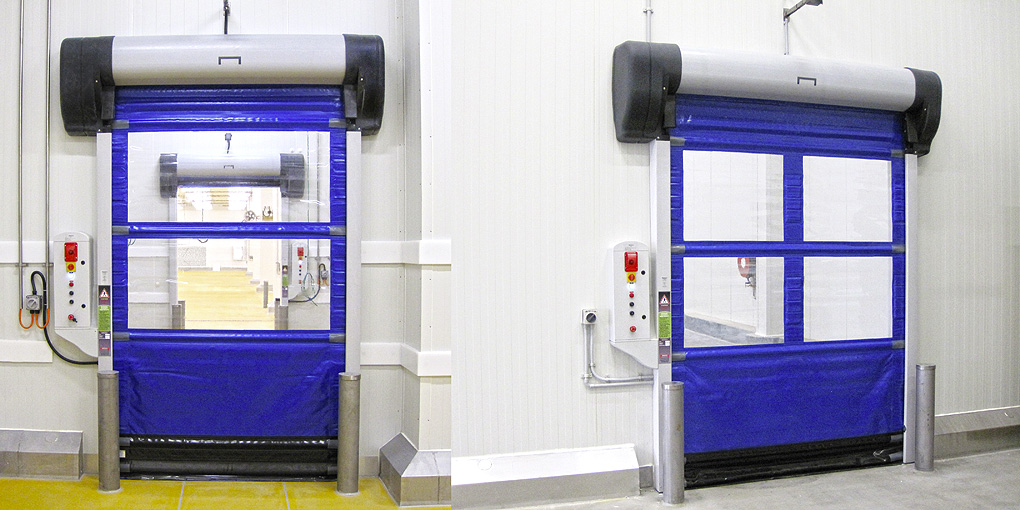

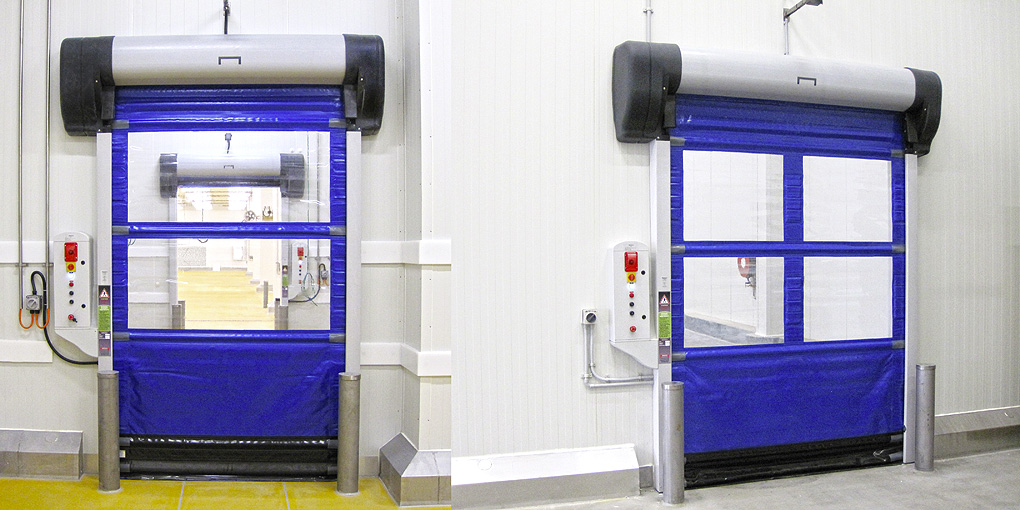

The fine, light and hard-wearing frame of the Nergeco multi-composites is perfectly suited to the walls of food processing rooms. Here, processing plants in Belgium.

Lastly, the multi-composite structure of the high-speed doors for the food processing industry is perfectly suited to an environment which uses panels.

‹

›

Need of washability and corrosion resistance?

The frames and mechanisms of Nergeco's food processes doors are made from new multi-composite materials. Developed from the start to cope with the rigorous constraints of the agri-food industry, they are more corrosion-resistant than 316L stainless steel.

In 1990, Nergeco developed its first Agro range with slim stainless steel frame, curtain with leaktight welds, complying with hygiene standards.

1999, pioneers of automatic high speed doors with multi-composite frame for the food industry, Nergeco's Agro 5 beats any expensive, heavy and unsatisfactory weld-fabricated stainless steel door. They anticipate the current food processes ranges.